FDM

FDM is a material extrusion method of additive manufacturing, extruded to create 3D objects for tooling, functional prototypes, and end-use parts. FDM makes use of a variety of thermoplastic materials, is accessible, reasonably efficient, and widely popular.

Advantages

- A wide range of materials including engineering grade thermoplastics are available depending on your application, purpose, mechanical and physical

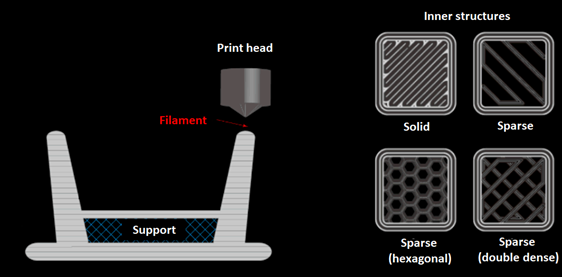

- It is possible to alter the internal structure of a part. (solid, sparse)

- Single FDM parts can be printed as large as x910 x y605 x z910mm.

- Several post processing methods can be performed including bonding, painting, and machining.

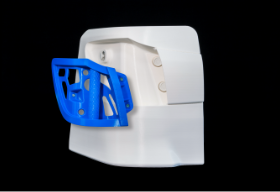

Applications

-

Bumper (actual size)

-

Headlight opening inspection jig

-

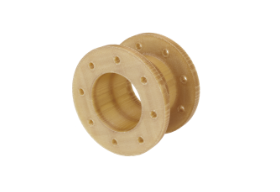

Connector

Printing Process

The standard FDM process distinguishes itself from other material extrusion techniques by using thermoplastics as feedstock materials typically in the form of filaments or pellets.

FDM 3D printer takes a polymer-based filament and forces it through a heated nozzle which melts the material. The nozzle, which moves moves horizontally layer by layer in a pre-determined path, deposits the material in 2D layers on the build platform which moves on horizontally and vertically.

Parts can be designed in a way that eliminates the need for support structures. As a result, once 3D printing is complete, the material that secures the model to the printer bed can be removed easily. By changing the internal structure, it is also possible to reduce weight while still ensuring the strength of the printed part.

To reduce printing time and save on materials, FDM printers typically don’t produce solid parts. Instead, the machine traces the outer perimeter (the shell) over several passes and fills the interior (infill) with an internal, low-density structure.

Modeling machines

| Machine | F 900 |

|---|---|

| Material | ABS-M30・ABS-ESD7・ASA・Nylon 6・Nylon 12・Nylon 12 CF |

| Maximum build envelope | x910 × y605 × z910 mm |

| Machine | Fortus 400mc |

|---|---|

| Material | ABS-M30・ASA・PC・PC-ABS |

| Maximum build envelope | x405 × y355 × z405 mm |

| Machine | F 370 |

|---|---|

| Material | ABS-CF10、TPU92A |

| Maximum build envelope | x355 × y250 × z355 mm |

Material Options

| material | grade | colour |

|---|---|---|

| ABS-M30 | ABS standard grade | Ivory and others * 1 |

| ABS-ESD7 | ABS anti-static grade | black |

| ABS-CF10 | ABS carbon fiber reinforced grade | black |

| ASA | ABS weather resistant grade | Ivory and others * 1 |

| Nylon 6 | – | black |

| Nylon 12 | – | black |

| Nylon 12 CF | Nylon12 Carbon Fiber Reinforced Grade | black |

| PC | – | White |

| PC-ABS | – | black |

| ULTEM™1010(PEI) | FAR certified grade | amber |

| ULTEM™9085(PEI) | FAR certified grade | beige / black * 2 |

| Antero™800NA(PEKK) | FAR certified grade | amber |

| Antero™840CN03 | PEKK Antistatic Grade FAR Certified Grade | black |

| ST130 | Material for disappearance model | – |

| TPU92A | Thermoplastic polyurethane | black |

NOTE:Please contact us for the colors other than ivory.

Black is not a FAR certified grade on combustibility for aircraft interior materials.