3D/CT SCAN

Make us become your 3D scanning partner.

Top of the line 3D software systems and software will be used on your project.

Yasojima Proceed offers comprehensive scanning capabilities. We have the tools and know-how to fulfill all your 3D scanning needs. We have experience with the latest technology and always pick the right software and 3D system for your job to ensure the best results.

- Extracting point cloud information from scans

- Output in polygon data (STL)

- Conversion to IGES/STEP, etc.

3D Scanning

- 3D color scanner (smartSCAN)

- Industrial Optical 3D Scanner (ATOS Core500)

- 3D Scanner (Laser) (FARO Edge Scan Arm HD)

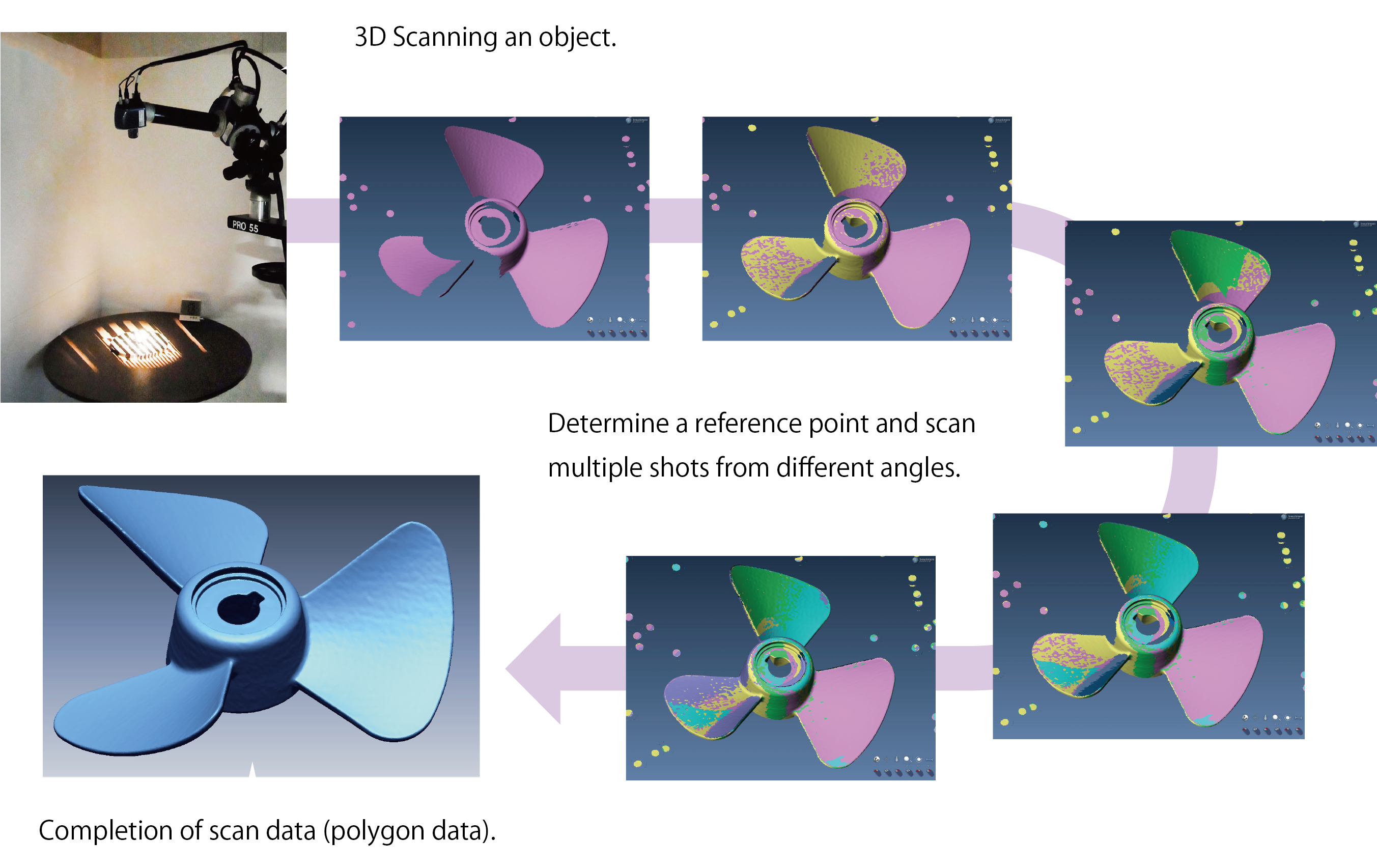

3D Scanning Process

| Scanning a real-world object | We describe a high-resolution, real-time 3-D shape measurement system based on a digital fringe projection and phase-shifting technique. It utilizes a single-chip digital light processing projector to project computer-generated fringe patterns onto the object, and a high-speed CCD camera synchronized with the projector to acquire the fringe images. |

|---|

| Data Optimization | Areas that are difficult to scan and where there are data omissions are corrected and edited using high-spec data correction software. We help you by improving and/or refining data for better accuracy, efficiency, relevance, and usefulness. |

|---|

| Completion of 3D data | STL is a file format commonly used for 3D printing and computer-aided design (CAD). |

|---|

CT scan

- DIMENSIONAL X-RAY CT SCANNER (ZEISS METROTOM)

- Micro CT scanner (TOSHIBA TOSCANNER-31300)

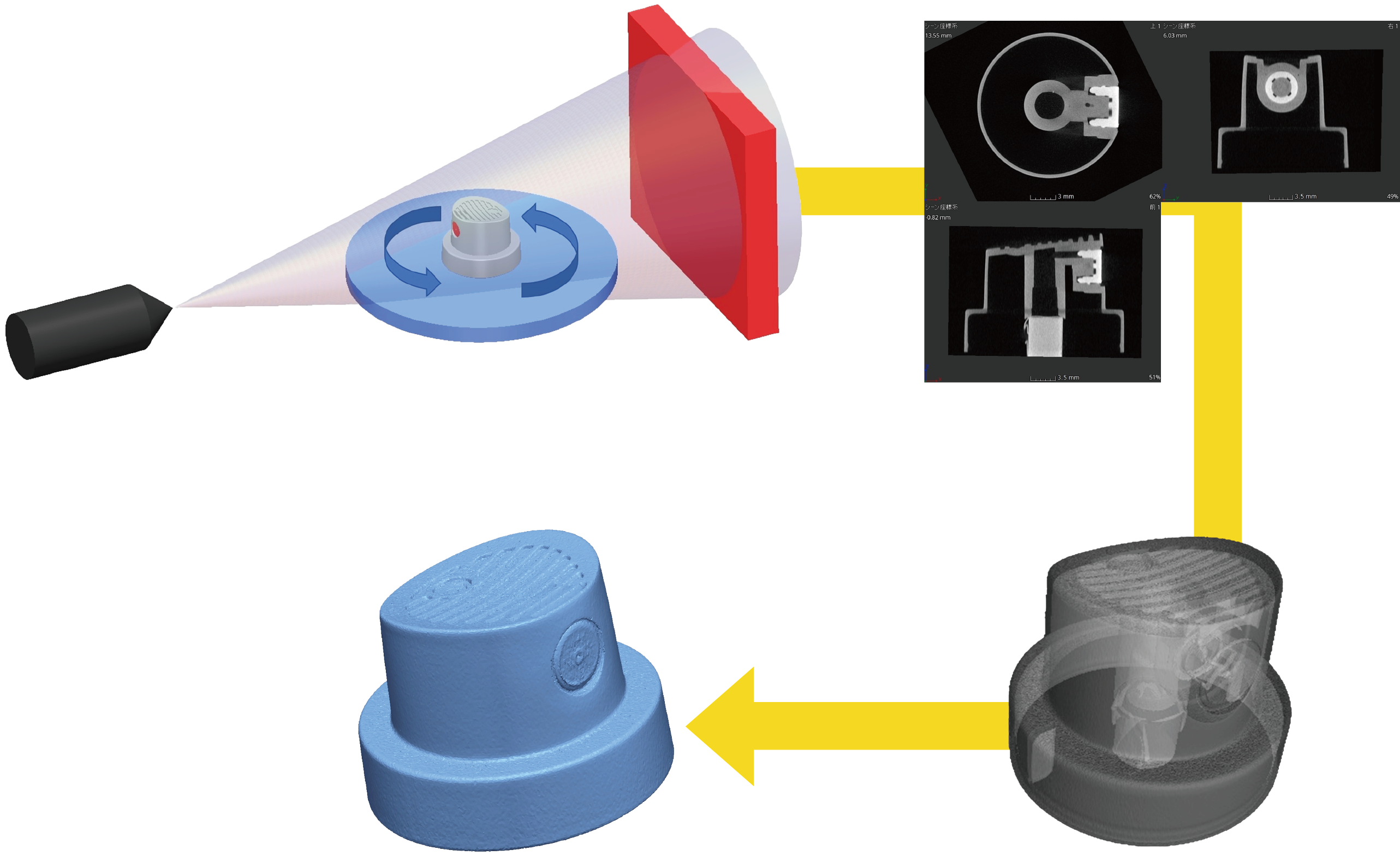

CT Scanning Process

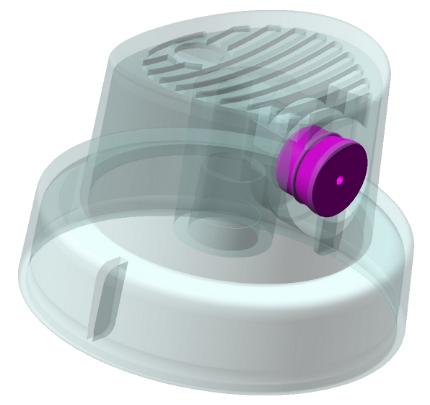

| Scanning a real-world object | An object is placed between the X-ray source and the X-ray detector, and the X-ray is irradiated from all angles by rotating the object, and the X-ray transmission data passed through the object is collected |

|---|

| Construction of tomographic images | Tomographic images from three directions are extracted from the collected X-ray transparent data. |

|---|

| Volume rendering | Continuous tomographic images are displayed three-dimensionally in three-dimensional space. |

|---|

| Completion of 3D data (STL data) | The 3D shape constructed by volume rendering is converted into 3D data (STL data) so that it can be used for various purposes. |

|---|

Applications of manufacturing innovation through scanning

3D CAD data creation (Reverse Engineering/Modeling)

Based on the scan data, we respond to all requests related to 3D data conversion, such as the creation of 3D data (STL) and conversion to intermediate files (IGES/STEP) that can be processed on 3D CAD, and provide highly reliable data. 3D data can also be used for reverse engineering and modeling.

Reverse engineering with 3D scanning

For cultural properties and other items that are difficult to exhibit even if you want to display them, we may create data by contactless 3D scanning, color the modeled based on the data, and use it as an exhibit. This tea set is a product that I created as an image sample.

Reverse engineering with CT scans

We convert 3D CAD data so that it can be used for CAD/CAM and structural analysis. Internal structures and parts made of different materials can also be accurately reproduced. Next-generation 3D technology will take the world to the next levels which we haven’t discovered yet in the fields of design and development.

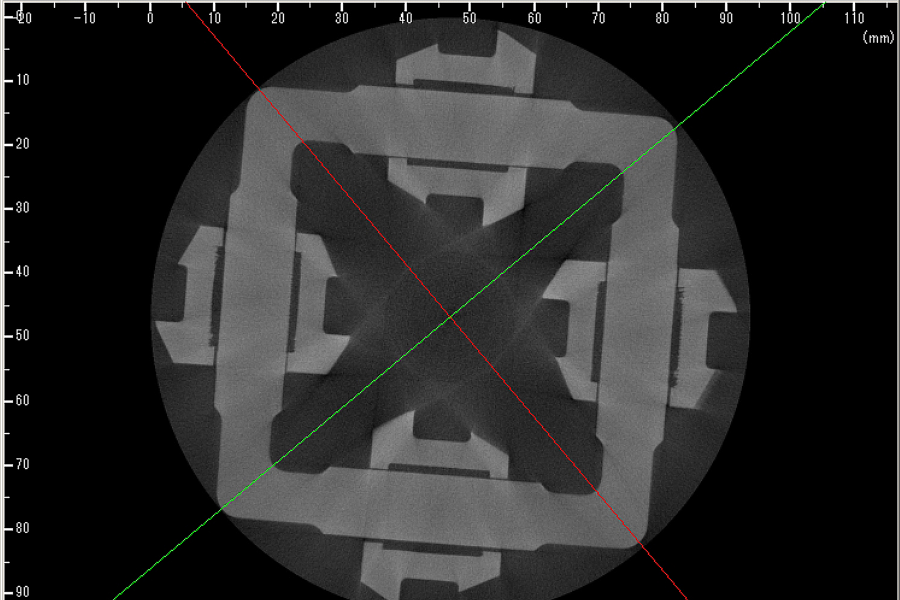

Comparative Verification

In the event of a defect after the completion of the product, such as a molded product, it may be necessary to verify whether the design data of the mold should be changed or the original design data should be changed.

At Yasojima Proceed, whenever we perform high-precision machining in-house, we have always been creating verification data to guarantee accuracy every time we deliver it to our customer; therefore, we can make the right proposals by utilizing our verification know-how to gain customer trust.

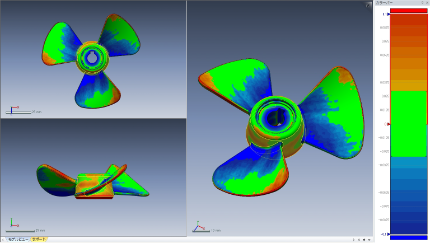

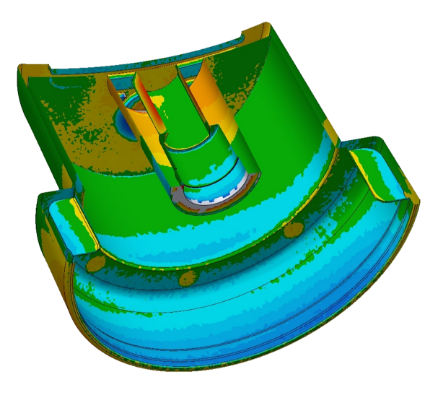

Verification with color mapping

The actual error between the actual design CAD data and the 3D scan data of the finished product can be expressed by superimposing the two data and creating a color map.

Quantifying specific errors

For products with high accuracy requirements, vision measuring systems and coordinate measuring machines can produce even more accurate values than scanned data. We also offer two-dimensional measurements to suit your budget.

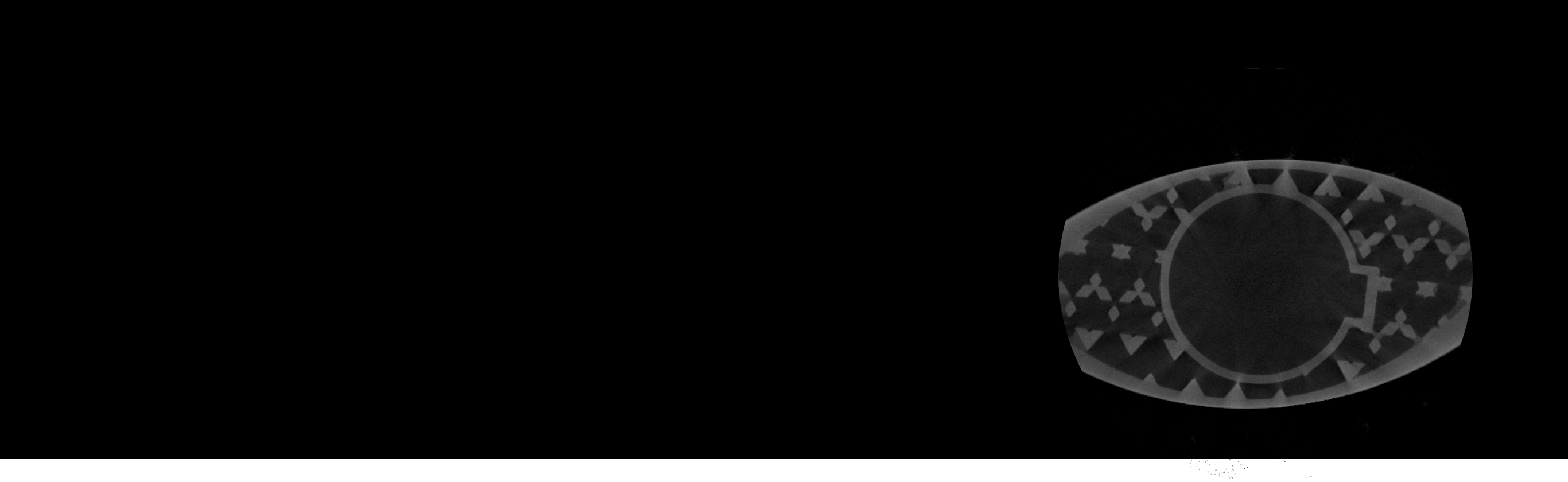

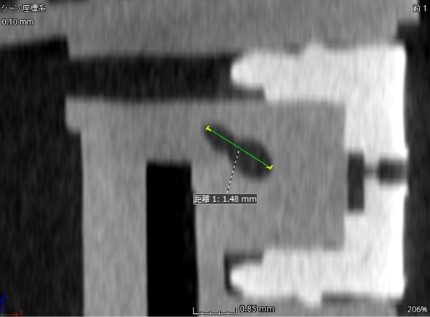

Visualization of Internal Structures

By irradiating the internal structure and voids that cannot be seen from the outside, it is possible to check and reveal the internal details of objects in three dimensions non-destructively.

Detection of voids

Detect voids that cause molding failures. Voids can reduce the strength of a product; therefore, early detection at the design stage is important.

Visualization of internal geometry

The ability to visualize the shape of the inside of the product and its cross-section, which cannot be observed by 3D scanning, makes it possible to compare and verify complex shapes using color maps.

On-site scanning services

Our on-site scanning team is made up of dedicated specialists that can quickly set-up a high-speed scanning environment at your location in no time. We have structured on on-site scanning service to be as affordable and convenient as possible for our customers. You can contact us anytime to learn more about how our on-site scanning services can benefit you.