FA・RoboticsCollaborative Robot

FA・Robotics

- Applications

- CASE STUDIES

Featuring shapes only possible with 3D printing

The COVID-19 pandemic and proliferation of non-contact and social distancing measure have increased even more demands for collaborative robots and machines.

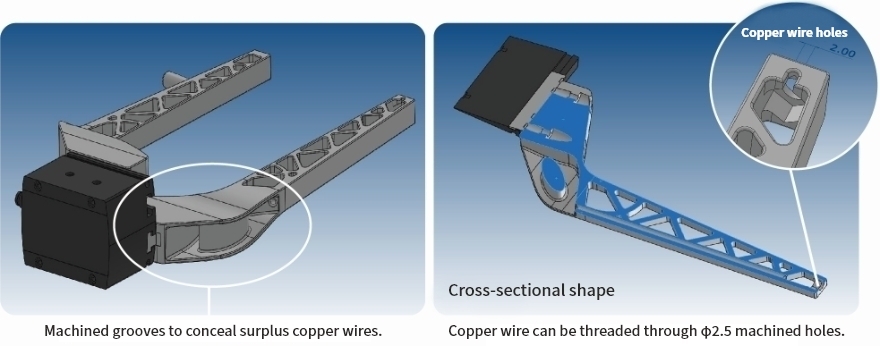

In response, Yasojima has been custom designing and manufacturing 3D printed robot appendages or “hands” that that can be attached to existing robots and machines; not something you can find off-the-shelf. We can also design and manufacture the mounting parts and mechanisms required to attach a hand to a robot or machine. Even fine holes through which wires need to pass can be integrated into your designs and manufactured in your end-use parts.

Yasojima takes a forward vision partnership approach dedicated to providing your company with full-service manufacturing and 3D printing strategies to deliver real results.

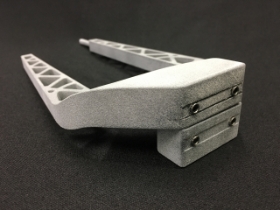

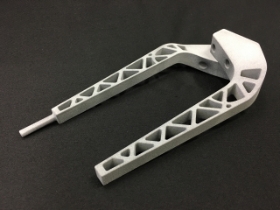

| Processing method | 3D printed with HP Multi Jet Fusion |

|---|---|

| Material | PA12 (Nylon 12) |

| Size | 230 x 80 x 30mm |

Case Study

Customer Concerns

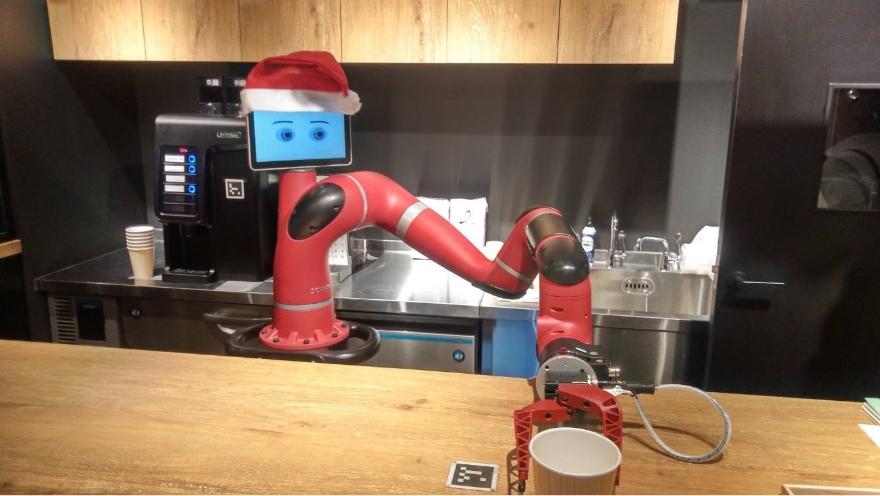

- We want to eliminate person-to-person contact and introduce non-contact measures.

- Off-the-shelf parts for this purpose are extremely difficult to source or unsuitable without expensive and time-consuming customization.

Customer Requirements

- The hand must be reliable, durable, and robust.

- The design should complement the atmosphere of our store.

- The hand must be able to be attached to the existing service robot and fit perfectly to perform its task; serving delicate paper cups containing coffee to our customers.

- The design, manufacture, and delivery of your solution is time-critical as our store installation schedule has been set.

Yasojima’s Solution

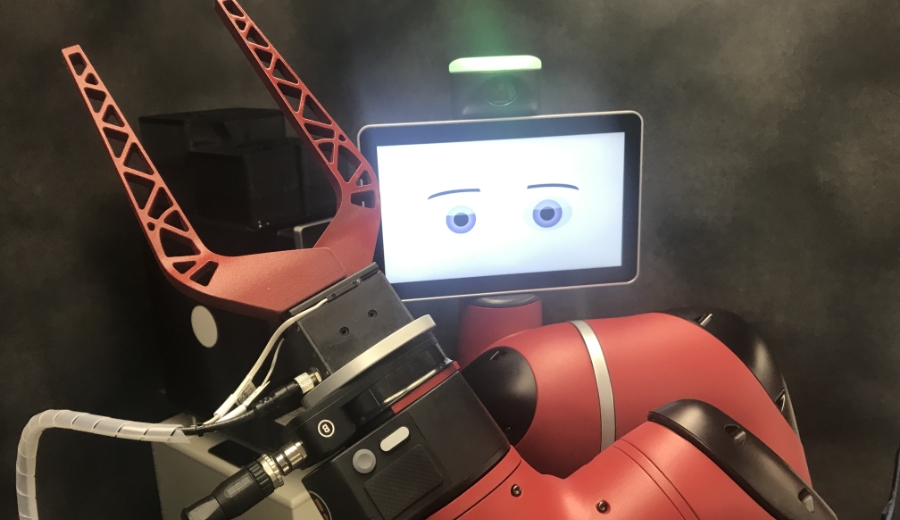

source: QBIT Robotics Inc.

Yasojima designed and manufactured an end-use part with characteristics that can only be achieved with 3D printing.

HP Multi Jet Fusion (MJF) 3D printing was chosen as it results in very little anisotropy (the property of being directionally dependent) and achieves the required mechanical strength and impact resistance.

Requirements such as φ2.5 wiring holes, color-matched painted surfaces, and a design that complements the atmosphere of the store were all incorporated. In addition, at only 114g, the end-use part weighs about 1/3 of similarly designed aluminum-made part (307g), which reduces the mechanical burden on the arm and motors, increasing their operating lifespan and reducing the intervals between costly maintenance.