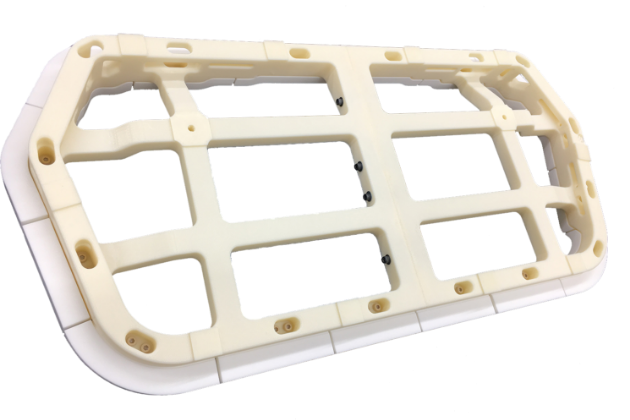

AUTOMOTIVEFront bumper inspection jig

APPLICATIONS

Take advantage of 3D printing

and high-precision cutting

Inspection jigs are used to confirm dimensional accuracy of parts on vehicle production lines that must adhere to strict quality controls. They are typically made of metal, heavy, cumbersome for assembly staff to use, and can lead to reduced productivity.

Yasojima can produce 3D printed automotive production aids and complex jigs that will significantly reduce the burden on workers and increase safety on the production floor.

| Method | 3D printed using FDM (Fused Deposition Modeling) SLS (Selective Laser Sintering) High-precision cutting |

|---|---|

| Material | ASA (Ivory) and PA2200 (Nylon12) |

| Size | 800 x 400 x 80mm |

Problems/Demands

Problems

- Handling heavy inspection tools is physically demanding on assembly workers who engage in repetitive work.

- The size and weight of existing inspection tools prevents extremely accurate and consistent results.

Demands

- Reduce the burden on workers and increase safety on the production floor.

- A durable and precise inspecting tool is required.

Proposal

Yasojima designed, prototyped, and produced a mechanically strong, integrally modeled part with a large 3D printing machine that allows for a modeling area of 910(x) x 605(y) x 910(z).

By designing and constructing the frame with smaller parts, it is possible to quickly and easily make repairs or replace an individual part that may become damaged, reducing operating costs. We used high-precision cutting to achieve a dimensional accuracy of ±0.2. This cannot be achieved using 3D printing alone.

Yasojima was able to replace the existing heavy and cumbersome metal inspection jig with one made with durable resin. The jig, which is currently in use on the production line, was reduced from 6kg to 3kg resulting in increased operational efficiency as well as less burden on workers and increased safety on the production floor.