Polyjet

PolyJet is one of the only 3D printing technologies with multi-color options and material combinations to produce incredibly realistic prototypes. A range of hardnesses (durometers) are also available.

Advantages

- Polyjet is capable of creating full-color, high-accuracy parts with the PANTONE colors.

- Choose a desired hardness or combine material properties into a single build.

- Shore A hardnesses of 30A, 40A, 50A, 60A, 70A, 85A, 95A, and rigid are available.

- Opaque and transparent photopolymers provide excellent visual detail.

Applications

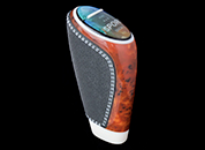

-

Shifter

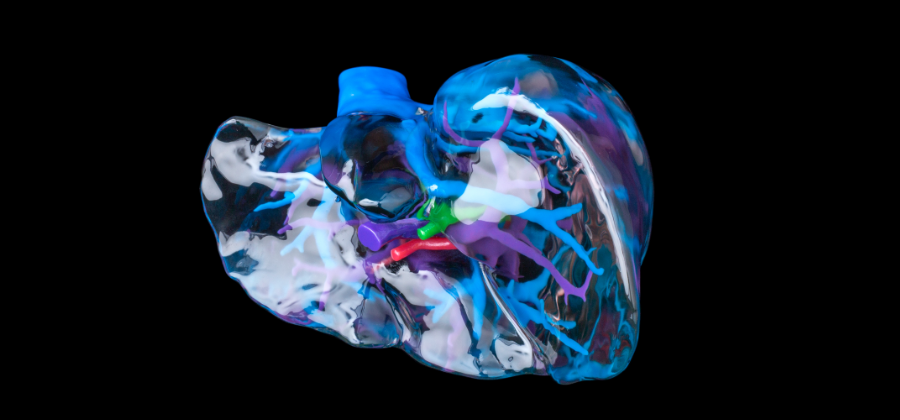

-

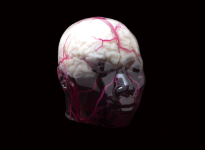

Human brain model

-

Container

-

Part sample (rubber-like material)

Printing Process

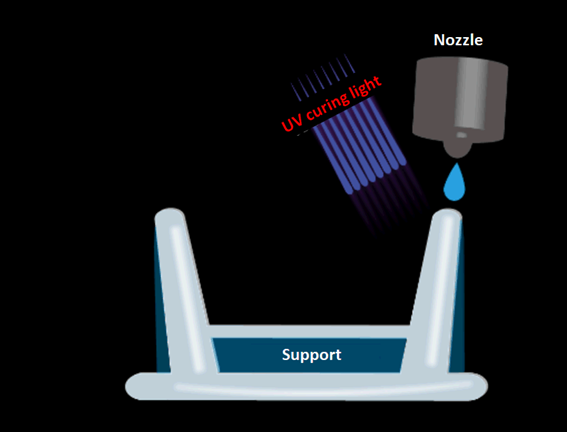

The liquid resin is heated to obtain optimum viscosity for printing. The print head then projects hundreds of micro-droplets of UV-sensitive photopolymer resin. A UV light, integrated in the print head, cures the material deposited and solidifies it to create the layer. Thin layers build up on the tray to create a precise model or 3D part. Multi-material and polychromatic printing is possible because the printhead holder has many nozzles capable of spraying several materials simultaneously.

Modeling machines

| Machine Stratasys | J750/Objet500 CONNEX3 |

|---|---|

| Material | Acrylic UV curable resin (PP-like, ABS-like, Rubber-like, etc.) |

| Maximum build envelope | x490 × y390 × z200 mm |

Property Comparison Tool