Binder Jetting

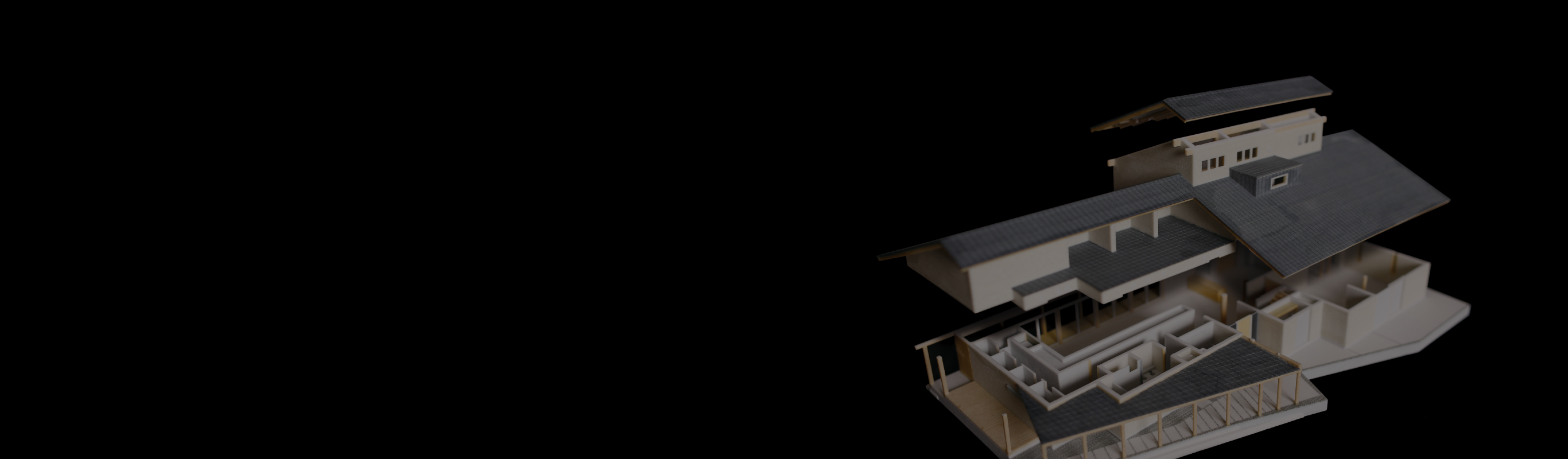

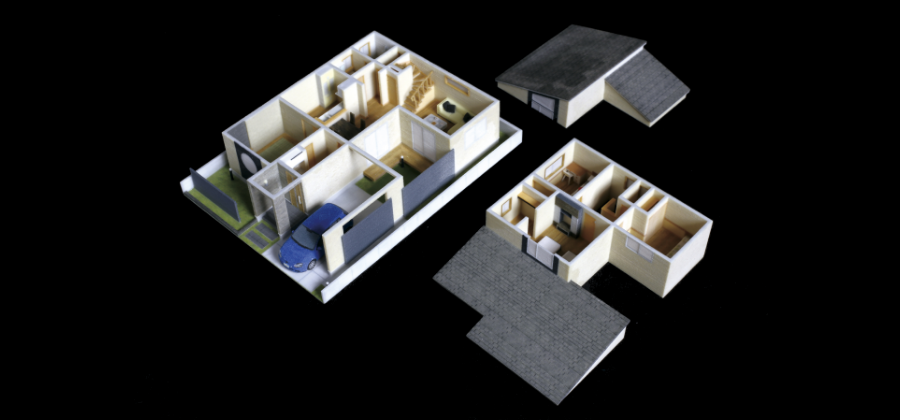

Binder Jetting is used in various applications, including the fabrication of full-color prototypes such as toys, figurines, and architectural models.

Advantages

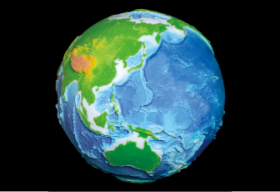

- Binder Jetting is capable of producing full-color parts.

- Binder Jetting provides an effective method to produce finished parts at nearly production-ready speeds.

Applications

-

Public facility model

-

Earth model

-

Figure

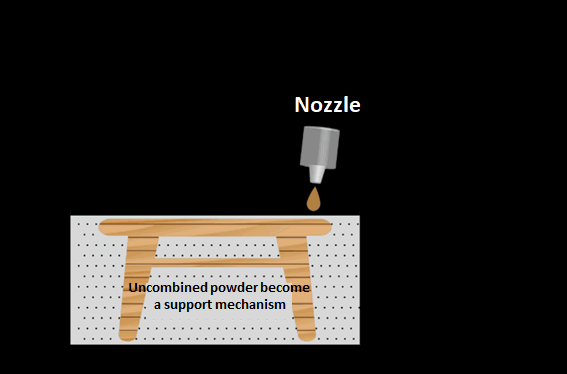

Printing Process

As with other 3D printing techniques, a recoating blade spreads a thin layer of powder over the build platform. A 3D print head with inkjet nozzles (similar to those used in desktop 2D printers) passes over the bed, depositing droplets of a binding agent that bond the powder particles together. In full-color Binder Jetting, colored ink is also deposited during this step. Each droplet is approximately 80μm in diameter which results in the production of high-resolution parts. When a layer is complete, the powder bed moves downwards, and the printer spreads a new layer of powder onto the build area. The process goes on layer by layer until all parts are complete.

Modeling machines

| Machine | Projet660 Pro |

|---|---|

| Material | Plaster |

| Maximum build envelope | x250 × y380 × z200 mm |