Powder Bed Fusion

Powder bed fusion (PBF) is an additive manufacturing, or 3d printing, technology that uses a heat source to sinter or fuse atomized powder particles together. Like other additive processes this is done one layer at a time until the part is completed. Yasojima offers specially-designed PPS for powder bed fusion 3D printing; a high-performance engineering plastic known for its excellent properties including high-heat resistance, mechanical strength, and dimensional stability.

Advantages

- Since PBF requires no support structure, parts with hollow sections can be printed easily and accurately.

- PDF allows Yasojima to print multiple parts simultaneously across the entire build volume.

- The appearance of PBF 3D printed parts can be produced to a very high standard using various post-processing methods such as dyeing, spray painting and machining.

- Yasojima offers one of the first PPS resin particle materials branded Toremiru PPS (Toraymill™PPS) developed by Japanese chemical and plastics manufacturer Toray Group.

Applications

-

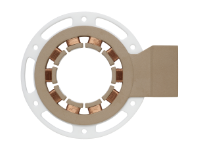

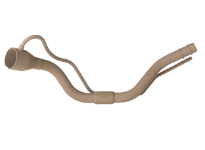

Resolver

-

Pipe

-

Connector

-

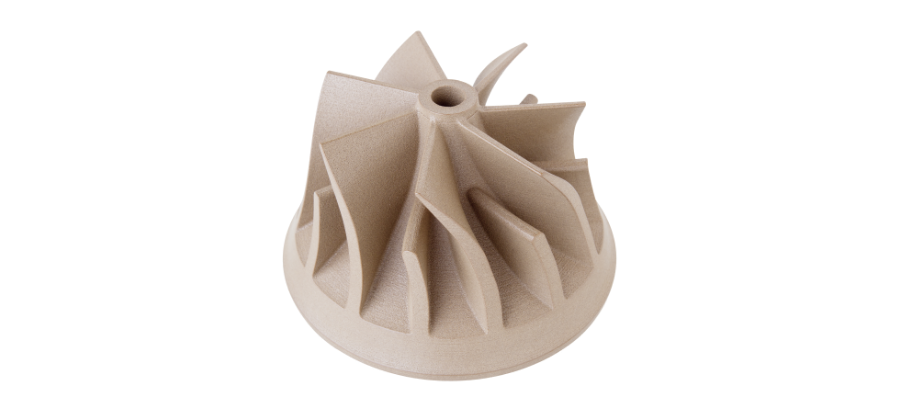

Part sample

(post-processing by machining)

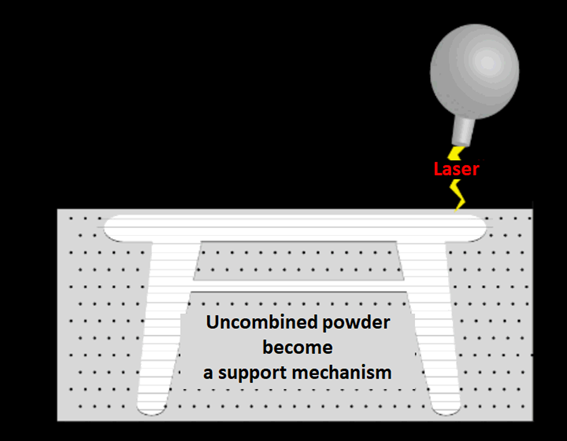

Printing Process

processes spread powdered material over the previously joined layer. A thin layer of material, approximately 0.1mm thick, applies to the build platform. A laser fuses the model’s initial layer, or cross-section. Each layer is then sequentially bonded on top of each other. A roller distributes a new coating of powder over the preceding one and additional cross-sections or layers are fused and added. It repeats the technique until the model is complete.

When the print job finishes, the part will be buried in the powder build chamber at the end. The unfused powder remains in place during post-processing, eliminating the unused powder. The fused part will stay attached to the build plate.

Modeling machines

| Machine | RaFaEl Ⅱ 550C-HT |

|---|---|

| Material | PPS・PPS CF・PPS GF |

| Maximum build envelope | x500 × y500 × z500 mm |

| Machine | RaFaEl Ⅱ 300C-HT |

|---|---|

| Material | PPS・PPS CF・PPS GF |

| Maximum build envelope | x300 × y300 × z410 mm |