3D Printing

In-house engineering staffs ensure the best results.

Yasojima Proceed will work with your organization to quickly develop the right solution for your needs. We can help you identify the critical-to-quality features of your project, define what mechanical and physical properties are key, select the most suitable machining and 3D printing materials, and present manufacturing options to suit your timeline and end-use goal.

There is a large range of printing technologies which varies with materials, technologies, applications, easiness, expensive etc. We, Yasojima Proseed, do not simply manufacture products based on data, but provide high value-added services by adding resin know-how to unique technologies backed by industry-leading experience and achievements. There are almost no examples of cutting manufacturers in Japan that have their own 3D printers and even their design department (technology center) in-house. Please use Yasojima Proseed’s total support capabilities to speed up product development, shorten production lead times, and reduce workload.

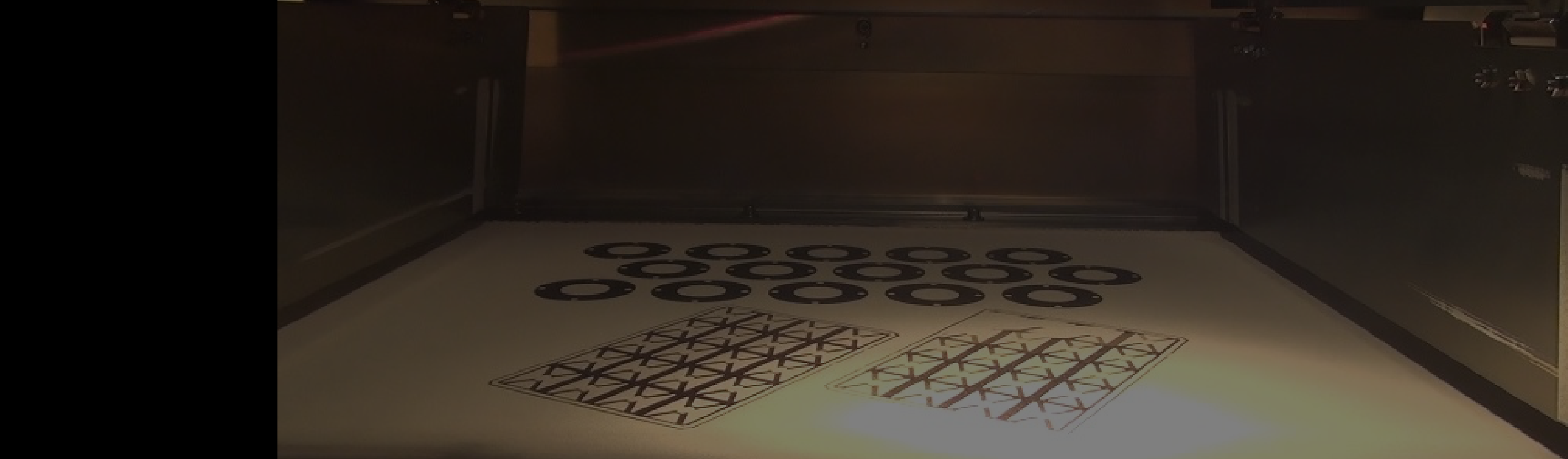

Powder Bed Fusion Process

3D printing technology that uses a heat source—typically a laser beam or an electron beam—to sinter or fuse atomized powder particles together.

Materials (powder)

- PPS

- Nylon12

- PP and Others

Advantages

- No additional base support is needed for printing.

- Can manufacture complex models without failures.

- Single parts can be printed as large as x670 x y360 x z560mm.

- Materials used offer consistent isotropic mechanical properties.

- Post processing can be done to better enable them in their intended applications.

Material Extrusion Process

3D printing technology that deposits a continuous filament of composite or thermoplastic material to build 3D parts layer by layer.

Materials (filament)

- ABS-M30

- Nylon12

- PC

- ULTEM™1010(PEI)

- ULTEM™9085 (PEI)

- Antero™800NA(PEKK)and Others

Advantages

- In order to retain the structural integrity of the part, the slicing software will create internal structures known as infill.

- Wide selection of printing materials available.

- Single parts can be printed as large as x910 x y605 x z910mm.

- Post processing can be done to better enable them in their intended applications.

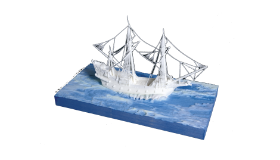

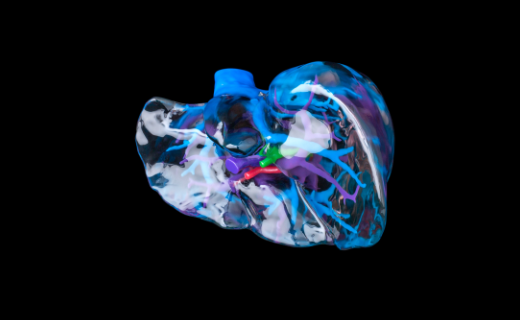

Material Jetting Process

3D printing technology in which droplets of build and support materials are selectively jetted onto the build platform and cured by either ultraviolet light or heat to form a 3D object.

Materials (liquid polymer)

- Transparent materials

- Full color materials

- Rubber-like materials

- PP-like materials

- ABS-like materials

Advantages

- Allows for full color 3D printing.(compatible with Pantone color ranges)

- Create custom shore values between A30 – A95.

- Print multiple materials at the same time.

- Creates near full transparency for the clear resin.