SLS

SLS is a great solution for rapid prototyping of functional polymers because it offers a high degree of design freedom and accuracy. It produces parts with consistent mechanical properties which means it can be used to produce parts that are very close to end-use quality.

Advantages

- The most widely used SLS material is PA200 (Nylon 12 white)

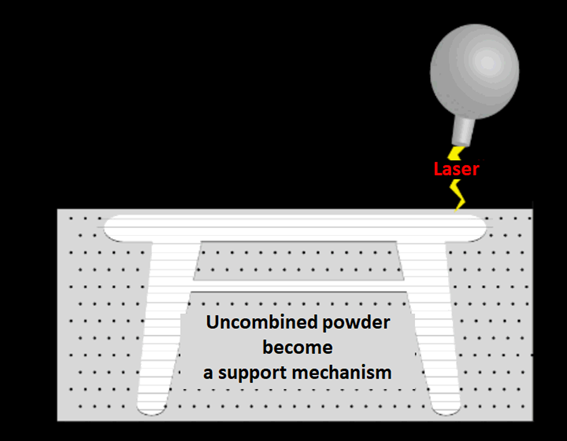

- Since SLS requires no support structure, parts with hollow sections can be printed easily and accurately.

- Taking advantage of the whole build volume is very important when printing with SLS, especially for small batch productions.

- It is possible to alter the internal structure of a part. (solid, sparse)

- Single SLS parts can be printed as large as x670 x y360 x z560mm.

- The appearance of SLS 3D printed parts can be produced to a very high standard using various post-processing methods such as dyeing, spray painting and machining.

Applications

-

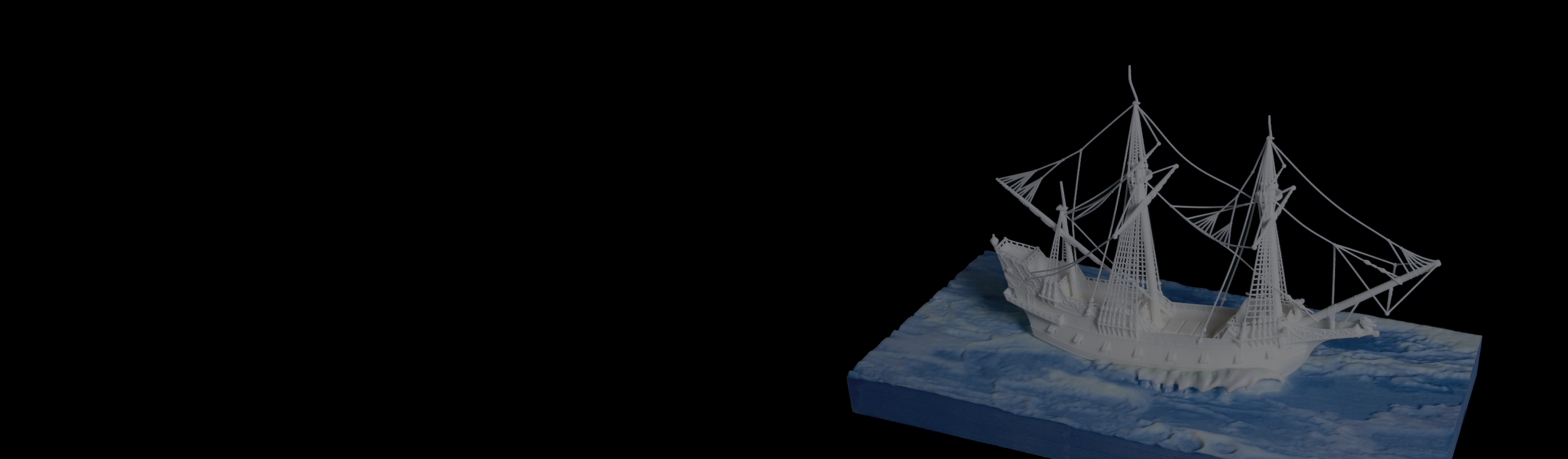

Mommoth model

-

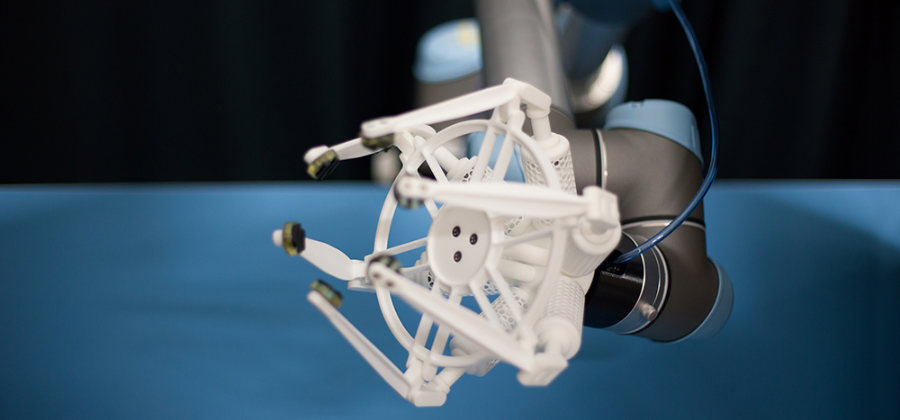

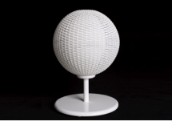

Lampshade

-

Honeycomb structure

-

Architectural model

-

Gear

Printing Process

SLS is an additive manufacturing technology that uses a high-power laser to sinter small particles of polymer powder into a solid structure based on your 3D model.

The entire cross-section of the component is scanned, so the part is built solid. After printing, the parts are fully encapsulated in the un-sintered

powder.

When the print job finishes, the part will be buried in the powder build chamber at the end. The unfused powder remains in place during post-processing, eliminating the unused powder. The fused part will stay attached to the build plate.

Modeling machines

| Machine | EOSINT P760 |

|---|---|

| Material | PA2200 |

| Maximum build envelope | x670 × y360 × z560mm |

| 装置 | EOSINT P396 |

|---|---|

| Material | PA2200 |

| Maximum build envelope | x320 x y320 x z570mm Corner R50 is attached to X and y. |

| Machine Formiga | Formiga P110・P100 |

|---|---|

| Material | PA2200 |

| Maximum build envelope | x190 × y230 × z310mm |