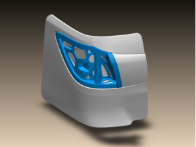

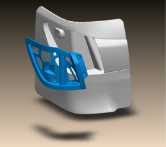

AUTOMOTIVEHeadlight opening inspection jig

APPLICATIONS

Suitable for a variety of lightweight structural applications

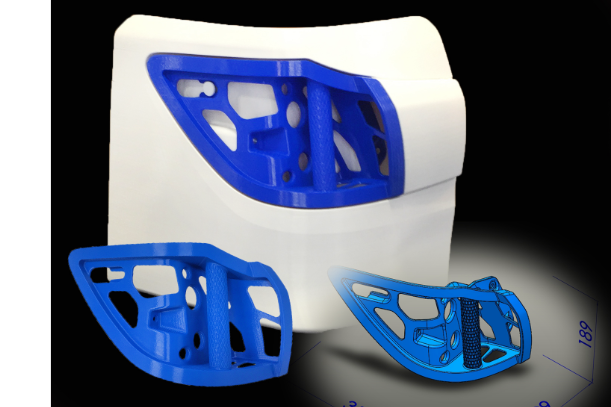

Inspection jigs and fixtures for checking the installation of automobile headlights have traditionally been made of metal, are heavy, and cumbersome for assembly staff to use. Reduce the weight of these tools by replacing metals with lightweight, high-accuracy, custom tooling made with plastics and alloys.

3D scanning is capable of creating highly accurate 3D plastic models of real objects. Yasojima can produce 3D printed automotive production aids and complex jigs that will significantly reduce the burden on workers and increase safety on the production floor.

| Method | 3D printed using FDM (Fused Deposition Modeling) |

|---|---|

| Material | ABS-M30 blue |

| size | 320 x 230 x 190mm |

Problem/demand

Problems

- Handling heavy inspection tools is physically demanding on assembly workers who engage in repetitive work. The size and weight of existing inspection tools prevents extremely accurate and consistent results.

Demands

- Reduce the burden on workers and increase safety on the production floor.

- A durable and precise inspection tool is required.

Proposal

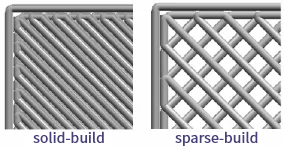

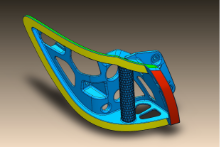

Yasojima designed, prototyped, and produced a sparse-structure tool with topology optimization to reduce the weight ten times, from 5kg to 500g. In addition, with the use of our 3D scanning technology, we were able to compare and verify that the lighter tool was identical to the original tool’s design data.